A power drill is a vital tool every handyperson should own. A drill is a cutting tool used for cutting holes into wood, metal, plastic, steel, etc., using rotation. Drills have various bits used for various materials.

These bits come in various shapes and sizes. They’re inserted into the drill and can be detachable. So, you may have one power drill with multiple drill bits. The two most common bits are the metal drill bit and the wood drill bit. Read on for more information.

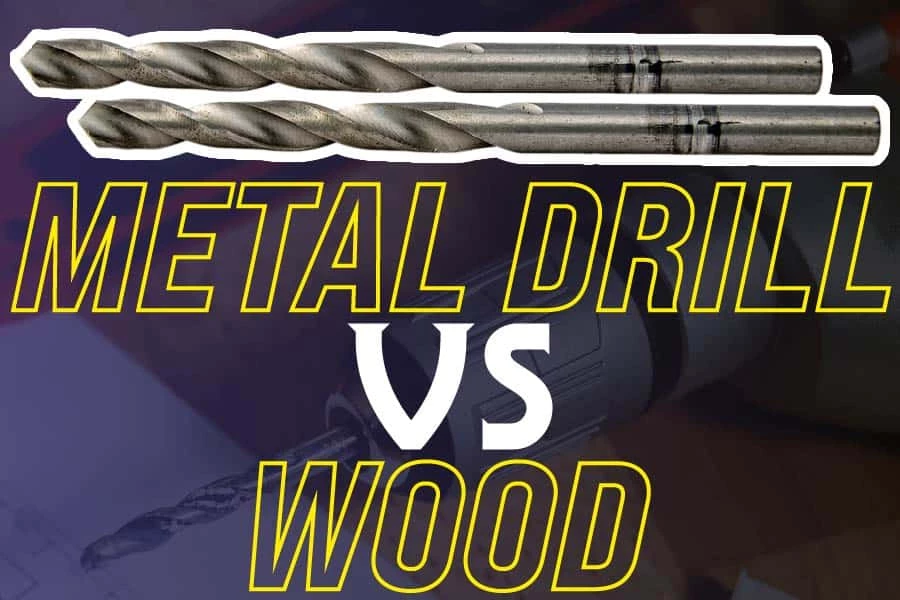

Metal Drill Bit Vs. Wood

A metal drill bit is a tool used for cutting holes through metal materials. It can also drill holes through wooden materials, although the finish may be rough unless the wood is light. All metal drill bits have an angular tip. They come in gold, copper, and black colors and have varieties.

On the other hand, a wood drill drills holes specifically into wooden materials with a nice finish. It can’t drill holes through metal objects because it may damage the bit. It comes in various varieties. Its main colors are black and silver (though other colors exist).

The major difference between a metal drill bit and a wood drill bit is geometry. They have different tip shapes, enabling them to smoothly create holes in the right material.

Some people have problems telling the metal drill bits apart from the wood drill bits. To identify which is which, first look at their tips. Metal drill bits have an angular tip, while wood drill bits are known for their signature brad point in the middle of their tip.

Secondly, every bit type has a specific design that distinguishes it from others. Lastly, do a drilling test if you’re still not getting it. Any bit that gives your wood a nice finish is likely a wood drill bit.

It’s advisable to own various sizes of these drill bits so you can easily work on any given wood or metal project.

Drill Bits

Drill bits are detachable bits used with a drill to bore different hole shapes in various materials. Drill bits come in various sizes, shapes, and types, all for various purposes. For example, drill bits attach to drills to make holes in materials using a rotation method.

Types Of Drill Bits

An electric drill: This is an electrically powered handheld drill driver.

Bench drill: Bench drills are powered drills, placed on a sliding frame, attached to a bench, and locked in. The larger sizes are known as “pillar drills” in the U.S.

Hand drill: This is a hand-powered and handheld drill driver.

Radial drill: It’s a pillar drill. Here, the pillar holds up the horizontal arm where the drilling head is placed. It allows the head to rotate well for the right positioning of the drill to make a perfect hole.

Pillar drills: You can place them on the table or the floor depending on their height, and they’re adjustable.

Drill bits are of different types, but metal drill bits and wood drill bits are the two most common types. Both the metal and wood drill bits are of different types.

Types Of Wood Drill Bits

Brad-point drill: This is the most common and accurate bit piece. Some people refer to them as the lip and spur bit. It has a pointy pin in the middle (a spur) and lips on either side of the tip. It’s very efficient and stable. It’s best used with handheld cordless drills or in a drill press. The Brad-point, or dowel bit, is used to make dowel joints.

A brad-point drill drills holes in composite wood, softwood, and hardwood. The holes are small but precise, often 1/8 inch (3mm) to 1/2 inch (12mm) long.

Hole saw: Perfect for boring smooth circular holes into wood. It can also cut through thin aluminum sheets and stainless steel with sizes ranging from 3/4″ (19mm) to 6″ (152mm).

Installer bits: This type of bit is used by electricians to bore long, thin holes through the wood to pass a wire or cable through. Its sizes range from 1/4″ (6mm) to 3/8″ (10mm).

Forstner bit: Benjamin Forstner patented this bit in 1874. It has an almost accurate design of two large gullets and a spur at its middle. This bit is a wonderful tool for boring flat-bottomed holes into wooden objects like plywood, softwood, and hardwood. It’s 1/4″ (6mm) to 2-1/8″ (54mm) long.

Auger bits: These have a spiral body with a screw-like tip. They’re good for drilling deep holes into wooden objects, leaving a clean finish, and they’re quite fast. They were preferable with a hand drill, but as improved versions emerged, they’re now better used with a power drill. They’re mostly 12″ long, but they can be smaller.

Spade bit or paddle bit: Spade bits are adequate for boring large circular holes in wood with no spiral design like a spur. The reason is that it has a flat body beneath its brad pointer tip. They are used mostly in plumbing, framing, and electric work, anything that needs a large hole. They range from 1/4″ (6mm) to 11/2″ (38mm).

Types Of Metal Drill Bit

Center bits: They’re perfect for drilling into milling machines, drill presses, or lathes due to their thick and strong, steady shanks. They drill very fast and leave a perfect hole with a perfect finish.

Twist bits: This is the most commonly used metal drill bit. It has a spiral design with a cone-shaped tip. The most common type is the HSS twist drill bit, and it’s quite cheap. It’s best for cutting through wood, plastic, and soft metals.

Twist drills comprise different materials, and each has advantages and disadvantages. They are made of high-carbon steel, high-speed steel, carbide, and cobalt. However, amongst these, carbide seems to be the most robust type.

Titanium drill bit: This bit is coated with titanium nitride at its tip, is best for cutting through steel (cast iron and stainless steel). The black-oxide coated bit is best used on aluminum, mild steel, brass, and copper. It offers a better tool life.

You need a tungsten carbide bit or cobalt drill bit for drilling through hard metals and tough alloy tool steels. If the material is hard steel, it’s better to use a masonry bit or a carbide bit with a tungsten carbide tip. You can sharpen your carbide bit, masonry bit, and cobalt bit.

Step drills: Step drills are adequate for drilling pilot holes and can’t drill holes deeper than the steps on their tip. It drills through fiberglass, sheet metal, thin plastic, some wood, etc. It’s known by various names: Christmas tree drill, multi-drill, cone drill, Unibit.

How To Sharpen A Drill Bit

It’s possible to sharpen your bits yourself if you don’t want to give them to a professional. Here, we’ll see how to sharpen a drill bit and the cautions to take before you begin sharpening your bit, you need to, first of all, find out if it needs sharpening.

To know if there’s a blunt edge, you’ll check for a glint of light on the cutting edge. If there is, then get set to sharpen your bit for efficiency and ease of use.

Step 1: Get your bench grinder out, and here, we’ll be sharpening a twist drill bit. Another piece of sharpening equipment you can use is the belt sander.

Step 2: This step is for first-timers. You need to know all the parts of the bit you’re holding so you can sharpen them accordingly. The lips are the first part. It’s the part used for cutting, and the twist drill bit lips are placed symmetrically to ensure equal cutting.

The second part is the land. It is the part after the lips. At the right position, it leaves a space between the lip and the job you are doing. The last part is the chisel. This line appears at the intersection of both sides of the land.

Step 3: It’s time to prepare the drill bit for sharpening. Run a flat-file through the drill bit, the land sides, and the cutting edge. Be careful not to get injured.

Step 4: If you’re using a belt sander, be sure to stay 60 degrees away from the drill bit and the belt sander. Sit properly and take the drill close to the rotating machine using a bench grinder. Be sure to keep the drill bit steady, precise, and parallel to the ground. Know that you’re creating a new tip.

Step 5: Carefully and precisely sharpen both sides of the cutting edge until you have a pointed tip. While sharpening, keep a lubricant close by as it can get very hot, so it doesn’t affect your hand.

Step 6: Now that you’re done sharpening, it’s time to test your work. Take the bit and drive it through the wood to make a hole. If it does, you’ve done a good job.

Conclusion

A metal drill bit is a tool used for cutting holes through metal materials. It can also drill holes through wooden materials, although the finish may be rough unless the wood is light.

On the other hand, a wood drill drills holes specifically into wooden materials with a nice finish. It can’t drill holes through metal objects because it may damage the bit. In addition, metal drill bits have an angular tip, while wood drill bits are known for their signature brad point in the middle of their tip.

Being Human

Being Human